The secret lies beneath the sand!

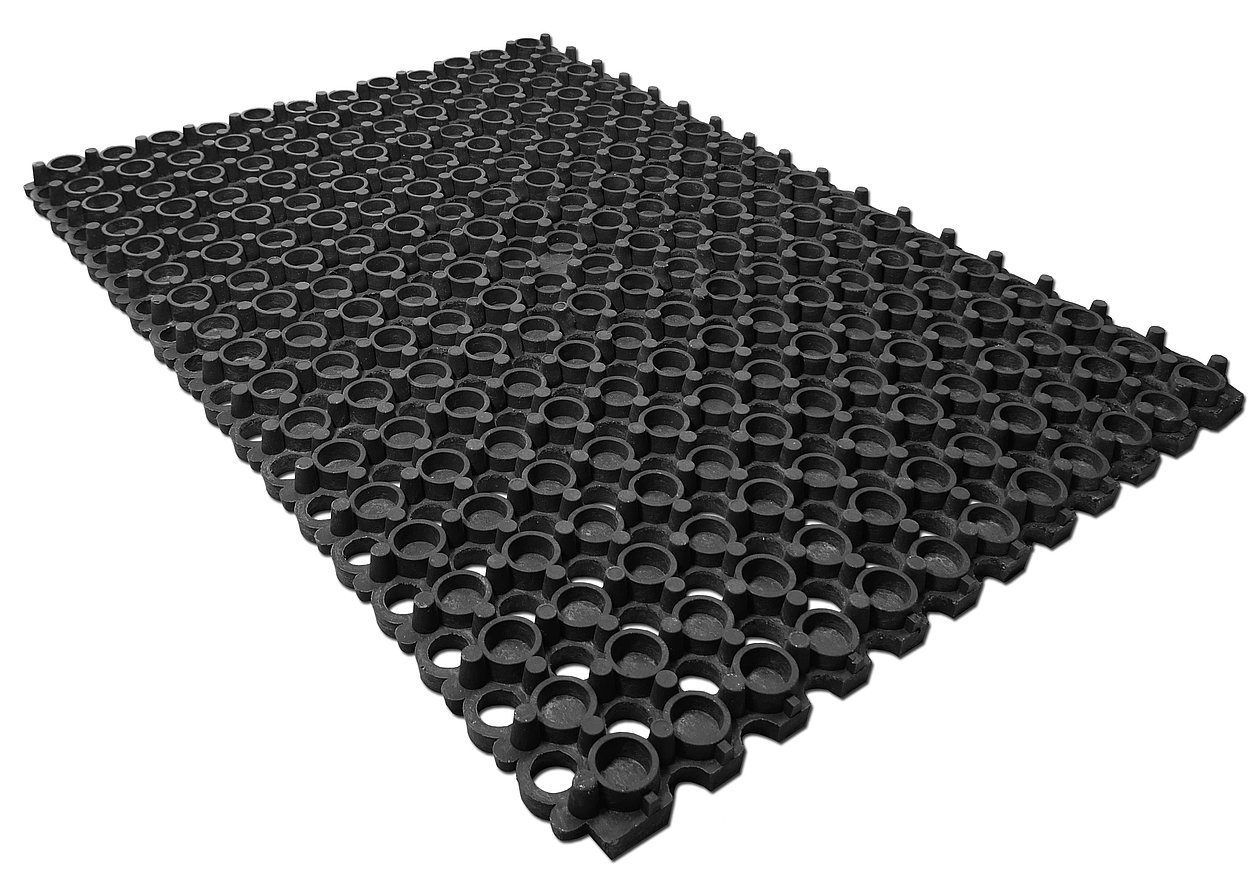

The OTTO-PerforatedMat™ has been developed specifically for equestrian sports and, thanks to its numerous functions, has an increasing influence on the safety, performance and longevity of the riding surface. It has been tried and tested thousands of times over, is installed worldwide and is often in use for decades.

The riding arena mat is just as popular with operators of the smallest hobby and therapy arenas as it is with large equestrian facilities and horse shows.

Why even our first customers are still enthusiastic today and the basis of the success of our PerforatedMat:

Features

Clean separation of the layers

With riding arenas that have an inadequate or no matting system, hooves can throw up stones and other materials into the footing after a very short time.

However, the OTTO-PerforatedMat™ creates a clean and permanent separation between the sub-base layer (generally gravel) and the footing (sand-textile fibre mix).

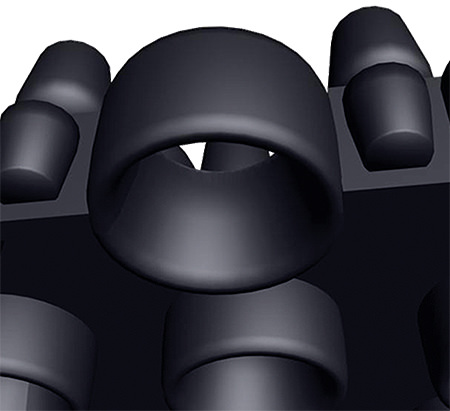

This is made possible using the integrated "sand locking rings", whose conical shape prevents sand from getting under the mat and prevents stones in the sub-base layer from migrating upwards into the footing. This is why the term “separation layer” is often used with the OTTO-PerforatedMat™.

The sand locking rings on the underside of the mat anchor the mat in place, therefore preventing any unwanted mat movement.

"We have been using the OTTO-PerforatedMat™s for over 20 years. In all this time, we have never experienced material from the sub-base layer getting into the footing. Nor does the sand migrate down into the other layers. So this really works brilliantly, and has done for decades.”

Klaus Balkenhol

Olympic Gold Medallist DressageWatch the full Interview here!

Puddles in the riding arena are not only a nuisance - many horses even refuse to perform the course because of them. In addition, muddy paddocks lead to unpleasant hoof diseases in the long term.

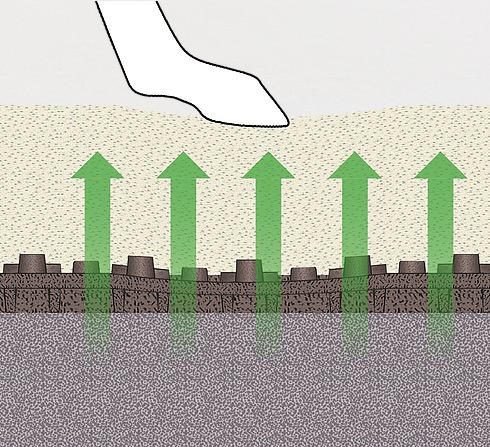

The solution: The OTTO-PerforatedMat™ allows all excess water to drain away quickly. When installed with the appropriate sub-base layer and a water-permeable footing, this means that not a single drop will ever remain on the top of the riding surface.

Muddy paddocks and a hazardous riding surface are now a thing of the past.

A total of 252 holes, each 3 cm in diameter, give the OTTO-PerforatedMat™ a 'drainage area' of 1,781 cm2.

Almost 18% of the total area of the OTTO-PerforatedMat™ is therefore designed solely to provide drainage.

Even after heavy, prolonged rain, the ground can be used at all times and the horses never have to stand in puddles or mud in the paddock.

“Previously, we had to cover the arena up with a PVC liner before every storm. And even then, we weren’t able to ride right after the rain stopped.

But ever since we installed the OTTO-PerforatedMats, the rainwater drains instantly. Even during the ‘El-Niño’ storms with up to 180 mm of rain, we are able to ride during the storm. This has been really fantastic.”

Shannon & Steffen Peters

Olympic Dressage RidersAs sand is a water-bound material, the footing must always be kept in an earth-moist condition to ensure that the horses have a secure grip and no dust can be stirred up. A riding surface that requires frequent watering can be very time-consuming, energy-intensive and costly.

The unique water storage system of the OTTO-PerforatedMat™ retains enough water to provide the surface with an even distribution of the required moisture over the surface and for a longer period.

Up to 4 litres/m2 can be retained in the cup-shaped water storage pockets on the upper surface of the OTTO-PerforatedMat™. This can rise to a water retention level of up to 10 litres/m2 when combined with the textile content in the OTTO ArenaTex footing!

In the case of outdoor arenas, rainwater can therefore replace the majority of the manual watering, which can save considerable costs in terms of tap water.

“I only water my outdoor arena twice a week because my OTTO Sport surface can store a lot of water itself. The surface is really simple to maintain and easy on the water supply.”

Billy Twomey

British show jumperIn equestrian sports, particularly show jumping, the ground is subject to extreme stress and high impacts. Considering the average weight of a horse is 600 kg, up to 5 tons of force are exerted on the ground with the impact of the first hoof when horse and rider land after jumping an obstacle.

The surface must be able to absorb a large part of this force to prevent short- and long-term injuries to the horse.

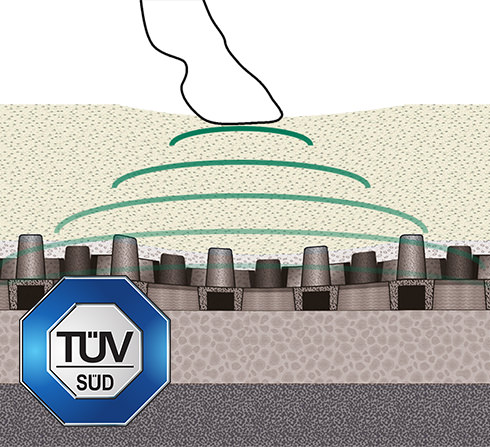

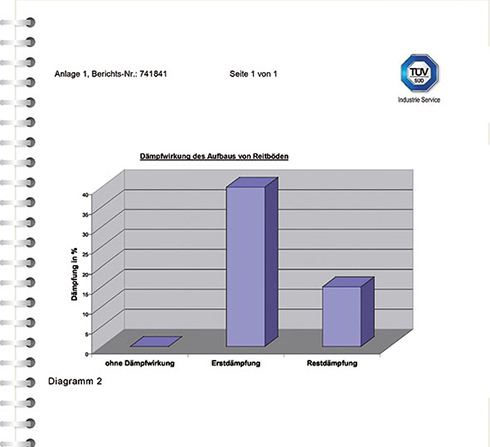

How can this be achieved? – With the OTTO-PerforatedMat™.According to a scientific study by TÜV-Süd (Technical Inspection Association), the OTTO-PerforatedMat™ absorbs up to 40% of the force exerted on the ground.

A large part of the force is therefore directed into the ground instead of the horse's legs, thus considerably reducing the strain on joints, ligaments and tendons.

"The construction of equestrian competition surfaces has settled by c. 40% when it is delivered. (…) The above research has shown that a cushioning effect of the described construction of equestrian competition surfaces is guaranteed.”

TÜV report on the study of the elasticity and cushioning effect of equestrian mats

Download TÜV certificate (PDF, 225 kb), Examination of OTTO perforated mats for compatibility (PDF)

In addition to shock absorption, however, an ideal riding surface must also be able to provide a spring-back effect for a portion of the force of the hoof striking the surface. This offers the horses more stability and improves their performance.

The OTTO-PerforatedMat™ has been designed specifically for this purpose.

The perfect thickness and density of the recycled PVC used in the OTTO-PerforatedMat™ means that it not only absorbs a large part of the impact force, but also provides effective cushioning for the horse's legs.

“During my decade-long career as showjumper, I have competed on countless different types of surfaces.

But every time I rode on OTTO Sport, a trademark of the surface was always an increased power when jumping off and accelerating.

This is one of the many reasons I chose OTTO Sport and their famous OTTO-PerforatedMats when I renewed my own surfaces at home and I have not regretted this decision once.”

John Whitaker

British show jumperWhat if a horse accelerates, makes a tight turn or stops abruptly? In these cases, it is crucial to ensure the hooves have a secure foothold and cannot slip.

If the footing is applied to a flat surface, it will shift under the force of the hoof. Even if the surface has a separation layer with studs of equal height, the horses will slip, as the footing provides no support in this case either and will ‘subside’, similar to an avalanche.

The system of high and deep knobs that is unique worldwide and the high- and deep-water storage cups on the upper surface of the OTTO-PerforatedMat™ provides an effective footing with adequate support which cannot slip, even when performing the tightest turns.

“What I really love about the OTTO-PerforatedMats is that you can just feel that the horses have more stability. Especially the horses like to go nuts and speed around, but they don’t slip and you can tell that they’re more confident. So, you really don’t have to worry about anything when it comes to safety.”

Alexandra Townsend

Australian event riderMany other separation layers have to be interlocked or installed butted up to each other.

As any plastic expands and contracts under temperature fluctuations, this can result in problems including ‘wavy’, undulating riding arenas, as the material has no ‘room for manoeuvre’.

Regardless of heavy rain, sub-zero temperatures or scorching heat, the OTTO-PerforatedMat™ exceeds all expectations.

After all, several million OTTO-PerforatedMat™s have been installed worldwide in a wide range of climates - and they all work!

Weather conditions cannot damage OTTO-PerforatedMat™s, as they are made of high-quality recycled plastic.

In conditions of high temperature fluctuations, OTTO-PerforatedMat™s can expand and contract with no problem at all, as they are installed with a small joint spacing between each mat.

“In my training arenas at my home in Riad, the OTTO-PerforatedMats are exposed to extreme temperature fluctuations. During summer, we get up to over 50° Celsius.

But the Mats can fully handle that and everything stays where it’s supposed to be. That’s what I call ‘German Engineering’!”

Ramzy Al Duhami

Saudi Arabian show jumperThe OTTO-PerforatedMat™ is produced using the highest quality materials, which guarantee the mats an extremely long service life. There’s a good reason why the OTTO DesertMat comes with a 20-year warranty for functionality!

If you do have to replace the footing after many years of use, you don’t have to touch the entire sub-base layer or the OTTO-PerforatedMat™. So, by replacing just the footing, your riding surface will be as good as new!

Even if you are aware of the importance of a high-quality indoor arena surface nowadays, the effort to achieve it can often be daunting.

You can relax with the OTTO-PerforatedMat™: Although the mats are one of the most tried-and-tested products in riding surface construction, they are very easy to install.

OTTO-PerforatedMat™s can be installed quickly and easily as, unlike other systems, they are laid using a small joint only, and require no interlocking or anchoring.

The mats can be easily cut to size (e.g. to fit the border of the arena), with any commercially available hand-held circular saw, jigsaw or chain saw. (Please ensure you wear the necessary protective clothing)

You will receive detailed installation instructions when you purchase your OTTO-PerforatedMat™s.

HOW CAN YOU BUILD YOUR OWN RIDING ARENA?

For instructions on how to BUILD A CLASSIC OUTDOOR RIDING ARENA, click HERE.DO YOU REQUIRE A COMPLETE TURNKEY CONSTRUCTION?

Would you like the experts to build your riding arena?

Our professional partner, OTTO SPORT, has 30 years of experience in riding arena construction and will realise your dream of your own riding surface.

John Whitaker

British Showjumper

“During my decade-long career as showjumper, I have competed on countless different types of surfaces.

But every time I rode on OTTO Sport, a trademark of the surface was always an increased power when jumping off and accelerating.

This is one of the many reasons I chose OTTO Sport and their famous OTTO-PerforatedMats when I renewed my own surfaces at home and I have not regretted this decision once.”

Shannon & Steffen Peters

Olympic Dressage Riders

“Previously, we had to cover the arena up with a PVC liner before every storm. And even then, we weren’t able to ride right after the rain stopped. But ever since we installed the OTTO-PerforatedMats, the rainwater drains instantly. Even during the ‘El-Niño’ storms with up to 180 mm of rain, we are able to ride during the storm. This has been really fantastic.”

Ramzy Al-Duhami

Saudi-Arabian show jumper

“In my training arenas at my home in Riyadh, the OTTO-PerforatedMats are exposed to extreme temperature fluctuations. During summer, we get up to over 50° Celsius.

But the Mats can fully handle that and everything stays where it’s supposed to be. That’s what I call ‘German Engineering’!”

Frequently asked questions

The OTTO-PerforatedMat™ is a riding arena mat that has been developed specifically for equestrian sports and is suitable for almost all disciplines (dressage, show- jumping, gallop tracks, lunging circle, paddock, etc.). For all other disciplines, including the "Western" riding style, please contact our team for professional advice.

The versatile function of the mats ensures optimum elasticity and skid-resistance, improves the water retention of the riding surface and allows a clean and permanent separation of the sub-base and footing layers. In addition, the OTTO-PerforatedMat™ provides elasticity and absorbs up to 40% of the force of the horse's hoof striking the surface.

The dimensions of an OTTO-PerforatedMat™ are c. 117 cm x 85 cm x 4.8 cm, and it covers a surface area of app. 1 m²; each mat weighs c. 17.5 kg. The colour, shape, size and weight of the mats may vary in the production process. However, this in no way affects the functionality. Complaints or exchanges in this respect are excluded.

OTTO-PerforatedMat™s have sand locking rings on the underside which fulfil a double function: on the one hand, their upwardly tapering shape ensures that no stones rise upwards from the sub-base layer into the footing, and on the other, they prevent the footing sand from getting under the mats and thus pushing them upwards. OTTO-PerforatedMat™s therefore ensure a clean and permanent separation of the footing and sub-base layer using the sand locking rings.

A varied surface structure is essential to avoid the risk of skidding or slipping. A surface with a low tread depth does not provide adequate support to the footing, and could detach from the sub-base layer like a surfboard, causing the horse to skid. The tread depth of an OTTO-PerforatedMat™ is pronounced and comprises a system of raised studs of 426 different heights (tread depth = approx. 2.6 cm).

The OTTO-PerforatedMat™ has a water storage system to reduce the risk of sand and dust being stirred up. The water storage system in the OTTO-PerforatedMat™ can retain up to 8 litres of water per square metre, and evenly distributes moisture to the sand footing via a capillary effect; the surface therefore retains the correct firmness.

The OTTO-PerforatedMat™ is made from elastic recycled PVC.

Our company is therefore making an active contribution to environmental protection and sustainable development, which is also supported by the EU.

The OTTO-PerforatedMat™s are installed offset with a joint distance of approx. 2-3 cm The numerous small raised studs and the water storage system must be laid facing upwards.

Similar to wood, OTTO-PerforatedMat™s can be cut to size with a saw; band saw, chainsaw, jigsaw, etc., but not with an angle grinder, because the material will overheat.

No, the OTTO-PerforatedMat™ simply remains fixed in place under its own weight (approx. 17.5 kg) and with the sand locking rings, and therefore requires no anchoring elements.

A functioning expansion joint is essential in the separation layer of a riding arena to allow for thermal expansion. Almost every material, particularly plastic, expands in the heat and contracts again on cooling. In this case, expansion would cause the connected separation layers to bulge upwards. This creates cavities under the surface which the sand then enters, preventing the separation layer from returning to its original position when the mats cool down. Over time, the mats will continue to migrate upwards. OTTO-PerforatedMat™s are installed with an expansion joint of approx. 2-3 cm. This, with the sand locking rings, prevents sand from penetrating the OTTO-PerforatedMat™s and they cannot gradually migrate upwards.

Due to temperature fluctuations, a functioning expansion gap is absolutely vital when installing a separation layer between sand and substructure. Every material, especially synthetic, expands when exposed to heat and shrinks when it gets colder. Interlocked separating layers without a functioning expansion gap will curve upwards after some time, creating hollow spaces underneath themselves into which sand can trickle. As a result, the separating layer cannot take its initial place anymore and, with time, will be pushed upwards.

The OTTO-PerforatedMats are installed with an expansion gap of 2 – 3 cm. In conunction with the sand-locking-rings, this ensures that sand cannot trickle underneath the Mats and push it upwards.

No, OTTO-PerforatedMat™s are installed with an expansion joint of approx. 2-3 cm. This, with the sand locking rings, prevents sand from penetrating the OTTO-PerforatedMat™s and they cannot gradually migrate upwards.

This is to filter out the fine particles that can form or be deposited in the footing, e.g. by the abrasion of the sand or by external components, e.g. leaves. This prevents these fine particles from entering the drainage and clogging it. In addition, the sand cannot trickle in an uncontrolled manner into the drainage layer.

To ensure water drainage. The water, which quickly drains through the PerforatedMat into the drainage layer, needs an outlet, as it would otherwise stagnate within the drainage layer on the base layer. This is ensured by installing on a gradient.

Where necessary, the topsoil can be stabilised with a gravel mixture base layer. A drainage layer of approx. 7 cm of coarse chippings with a grain size of 8/16 mm is then placed on top of this layer. The OTTO-PerforatedMat™s are then installed on top of the drainage layer.

No. Round gravel should not be used because, unlike chippings with a grain size of 8-16 mm, it does not interlock and can move around. This will mean that the OTTO-PerforatedMat™s are not sufficiently stable.